Projects

Engineering unique heavy-metal separation equipment to enhance production efficiency

Corsicana, TX, USA

Metal Separator Plant

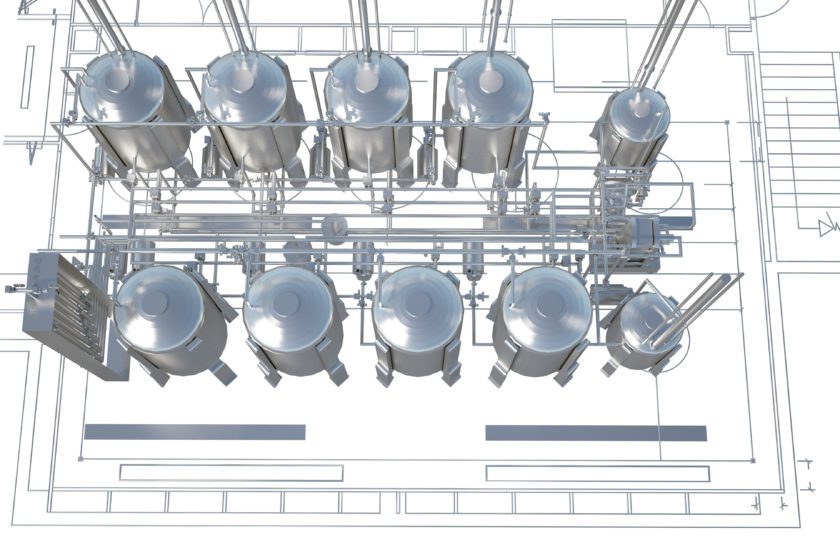

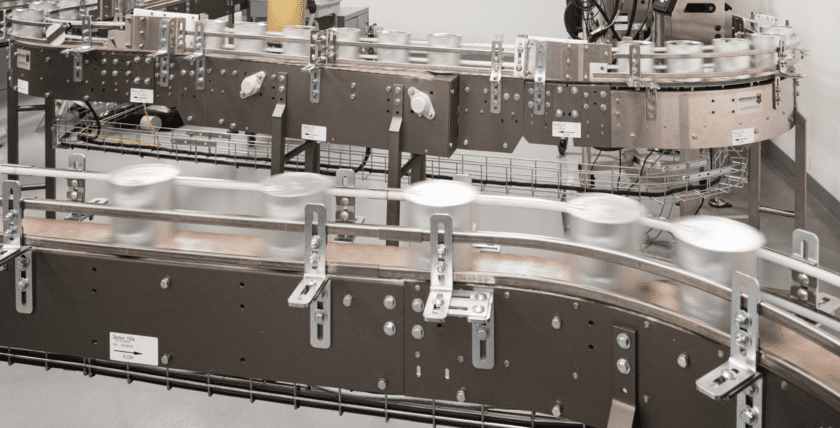

Audubon Metals’ heavy-metal separator and aluminum alloy reprocessing plant uses a unique material separation device to separate aluminum alloy from shredded vehicles (zorba). Separated aluminum is melted and cast into small ingots, then packaged for shipment. It took seven months for the original design to be completed and installation was ahead of schedule.

Among the material handling equipment Salas O’Brien designed and managed were conveyors, eddy currents, trommels, vibratory feeders and screens, drum separators, dryers, baghouses, melting furnaces, and ingot production lines. In addition, multi-material separation is possible with this plant, including aluminum, steel, plastics, paper, coins, and many others. Our efficient equipment design results in the process taking approximately 42 days from the point of shredding an automobile to the point of shipping the aluminum ingots.

Process Engineering, Structural, Civil, Architecture & Interiors, Mechanical, Electrical, Plumbing and Fire Protection, Digital & Automation

2021

160,000 square feet

$37 million

Skanska