Projects

Fast-tracked design, procurement services to expand capability

Wanamingo, MN, USA

Powder Infant Formula Process/Packaging Expansion

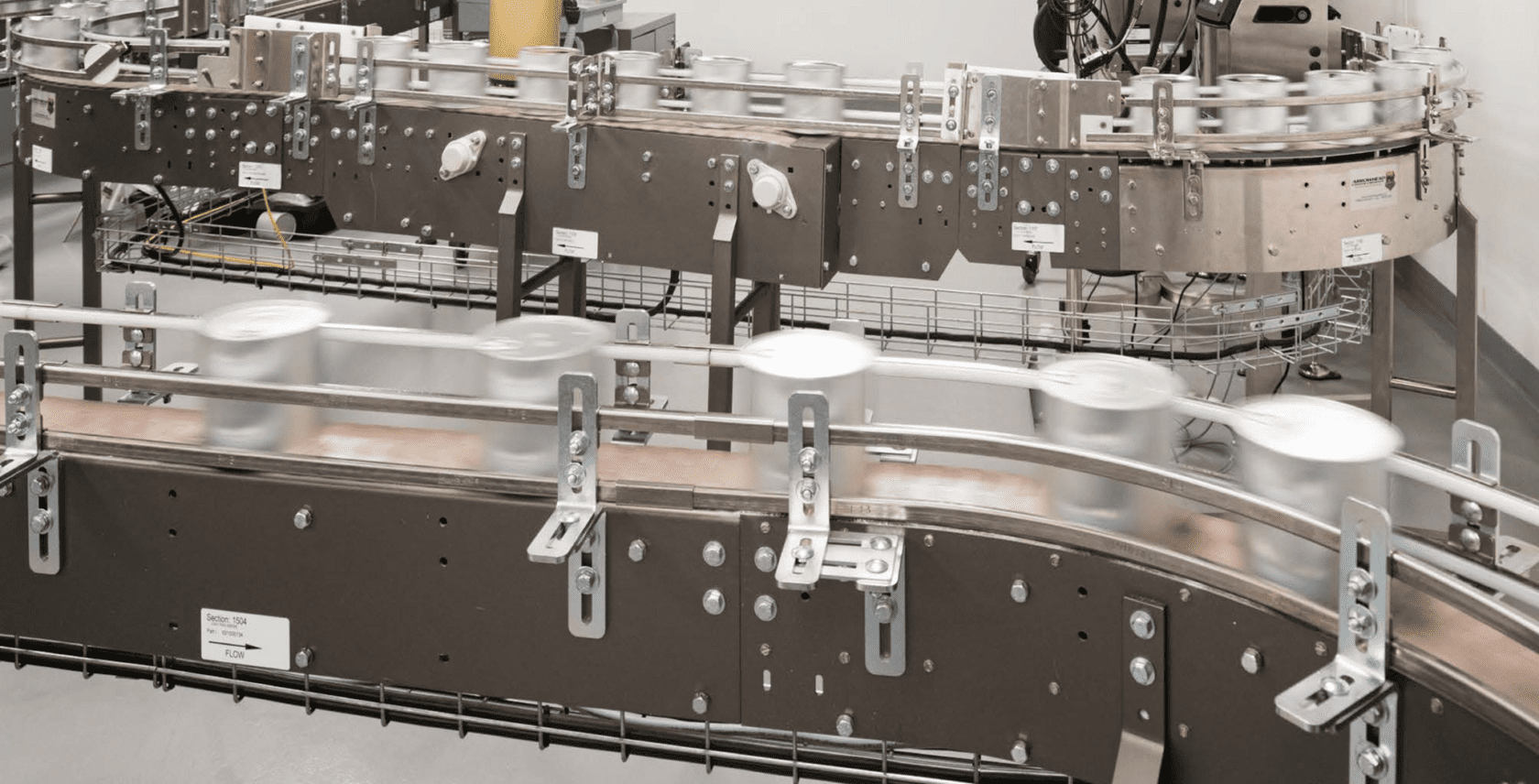

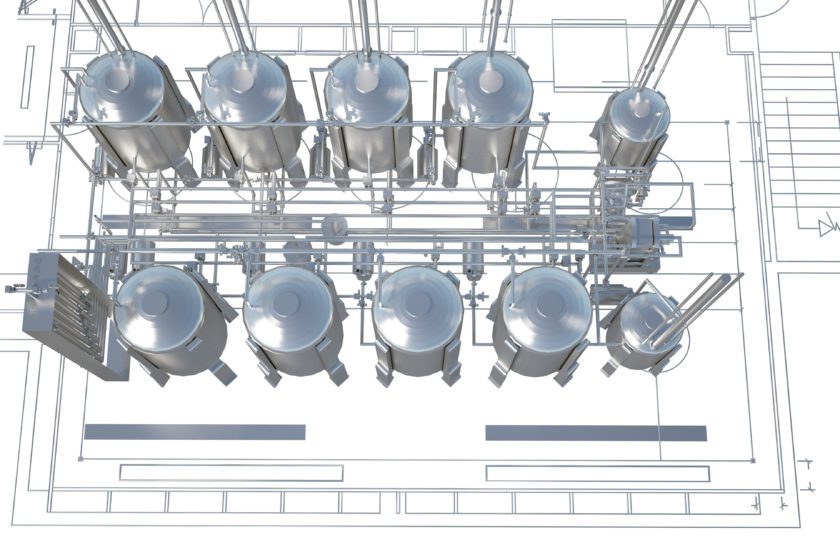

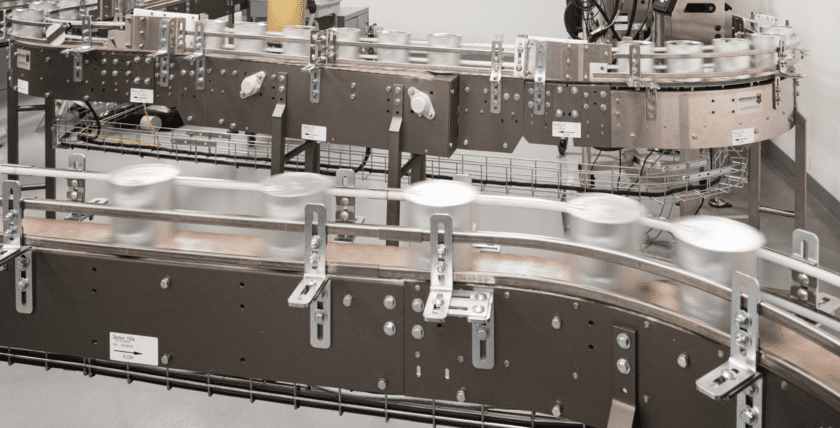

Salas O’Brien designed, specified, and procured process packaging and facility equipment for this infant formula manufacturing plant. We used the engineering, procurement, and construction (EPC) model to expedite completion.

We worked with the owner to develop conceptual and preliminary designs to fast-track the progress. We applied a two-phased delivery approach to ensure the facility shell and warehouse storage could be constructed and dried before winter. To minimize product contamination and bacterial growth risks, we designed cascading airflows in the facility and packaged the product using compressed air, CO2, and nitrogen. Additionally, we developed production rooms and equipment made from materials that are easy to clean and won’t stimulate bacterial growth. Our team managed all aspects of the project, including design, construction, procurement, and equipment start-up/integration.

2016

53,000 square feet

$24.5 million

Skanska