Projects

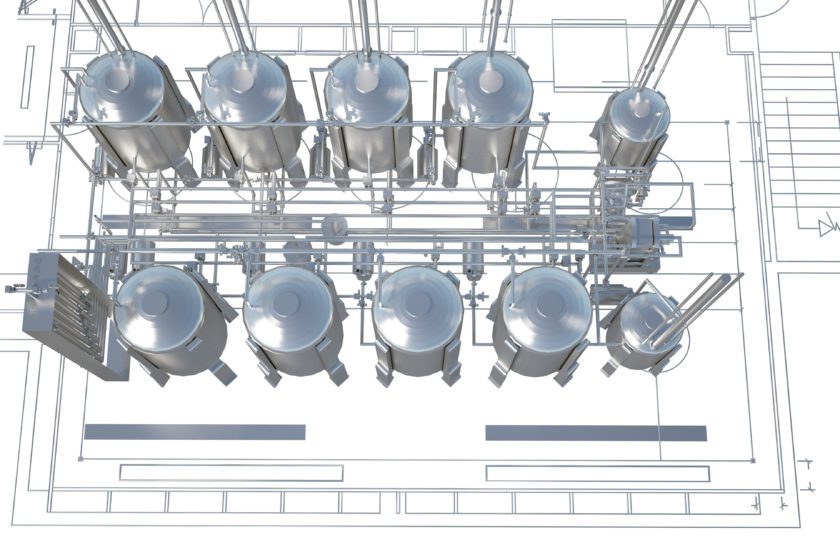

Expanding infant formula finished product tanks for product variability

Midwest, USA

Finished Tank Expansion

The number of available finished product tanks was limiting our confidential client’s infant formula production. Salas O’Brien assisted this global nutritional manufacturer in integrating three new 30,000-gallon finished product tanks, each with a new pump and a new product hookup station. We connected the new tanks to the plant’s two existing main liquid infant formula processing systems through the central product hookup station. Clean-in-place (CIP) of the tanks and associated piping was accomplished by tying into an existing CIP system and replacing the current pump for increased capacity. The new tanks were cooled using the plant’s frigid water system and instruments monitoring temperature and pressure through the jackets. In addition, a new tank alley was constructed to accommodate the newly finished product tanks and their respective alcoves, valves, product hookup stations, and pumps. We handled all process, architectural, structural, mechanical, and electrical engineering and design required.

Bulk Material Handling, Mechanical, Electrical, Plumbing, Process Engineering, Digital & Automation, Structural

2018

CCC Group Industrial Construction