Projects

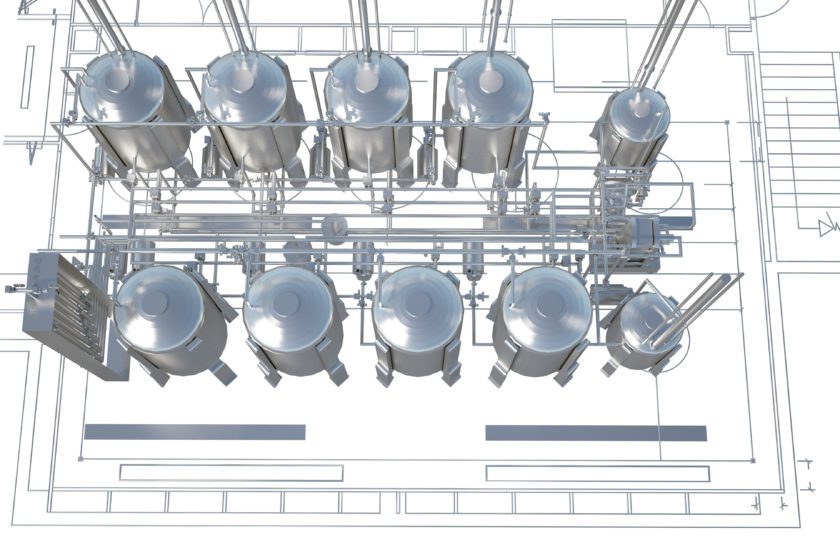

Redesigned flavor injection system increases capacity and reduces waste

Confidential Major Coffee Manufacturer

Montreal, QC, Canda

Montreal, QC, Canda

New Coffee Flavor Injection System

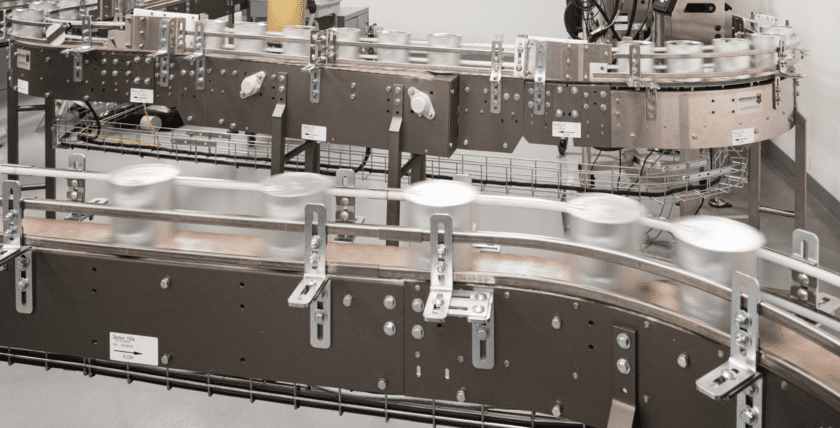

When our client needed to increase the production of coffee flavors, our team redesigned the oil and flavor injection system to increase capacity and improve quality – while still keeping safety in mind. The new installation included an automatic cleaning and pipeline pigging system that ensured a fast transition between flavor changes, reducing downtime and improving throughput. As a result, yield increased, leading to greater efficiency and less waste.

A streamlined process controlled by instrumentation replaced bulky raw material operations. We provided design, engineering, and project management services.

Services

Mechanical, Electrical, Plumbing and Fire Protection, Process Engineering, Digital & Automation

Completion Year

2019

Construction Cost

$5 million

Project Partner

GEA Tuchenhagen