Projects

Process and packaging upgrades drive efficiency and sustainability

Montreal, QC, Canada

Process and Packaging Upgrades

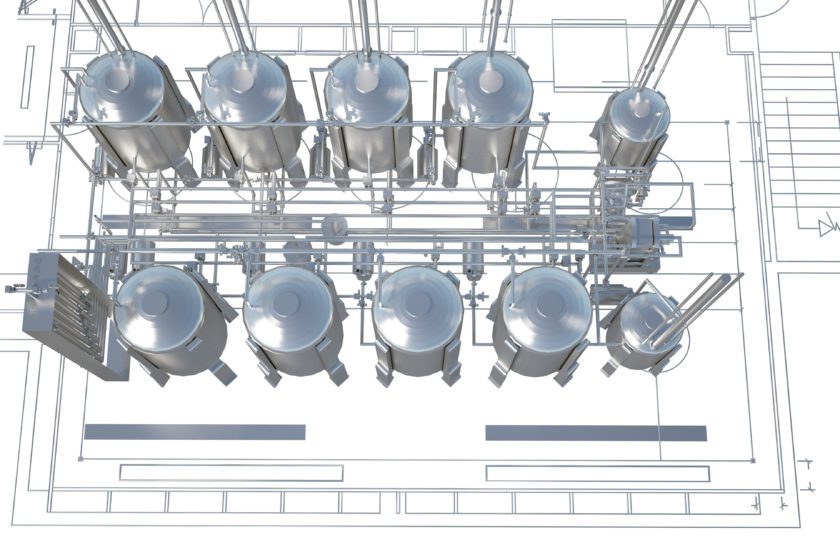

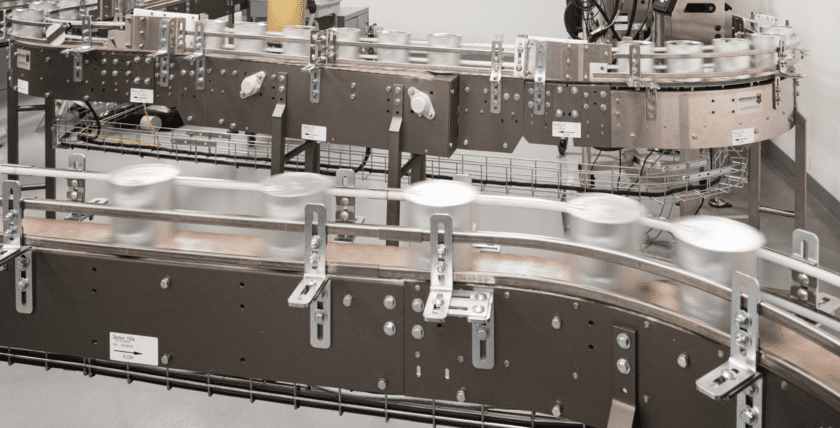

To keep up with growing demand, Labatt Breweries of Canada wanted to upgrade production capacity and improve sustainability in its Montréal facility. The solution developed across three phases. In the first phase, our team led equipment selection and integration for a new can line capable of producing 2,000 cans per minute. The second phase included leading process engineering to add flavor injection and expand capability to support new products, and the final phase expanded production lines to include Corona and Stella Artois brands. Despite a global pandemic, we installed the new packaging system on an expedited schedule of eight months versus the typical 12-18 months.

The first of its kind in North America, the system uses mostly recycled fiber paperboard instead of plastic. This sustainable solution reduced Labatt’s overall single-use plastic weight by nearly 335,000 pounds (152,000 kg), which is the approximate equivalent of 117 mid-sized cars.

2021

$55 million

Frare & Gallant Construction, Thomas O’Connell, C. Frappier Electrique