Projects

Turnkey project and 40 percent increase in processing capacity

Middlebury Center, PA, USA

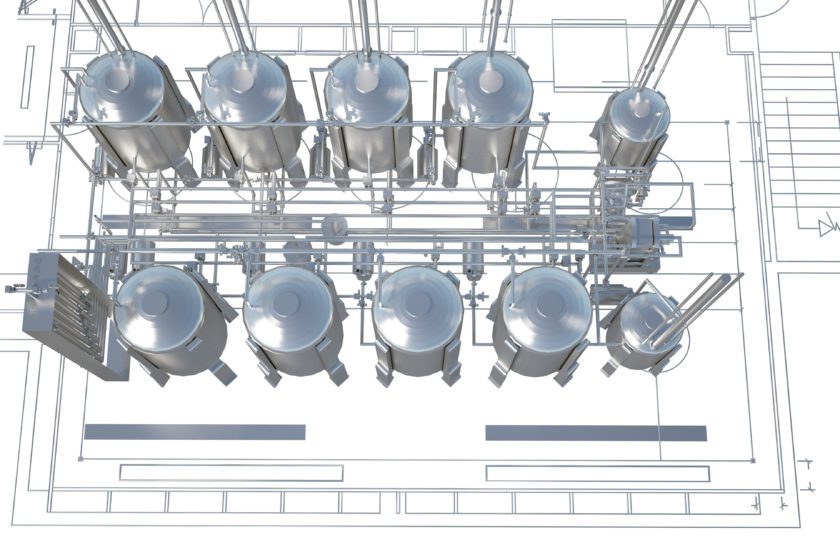

Milk Balancing Plant

Dairy Farmers of America (DFA) operates a milk balancing plant that produces dry skim milk powder and liquid cream.

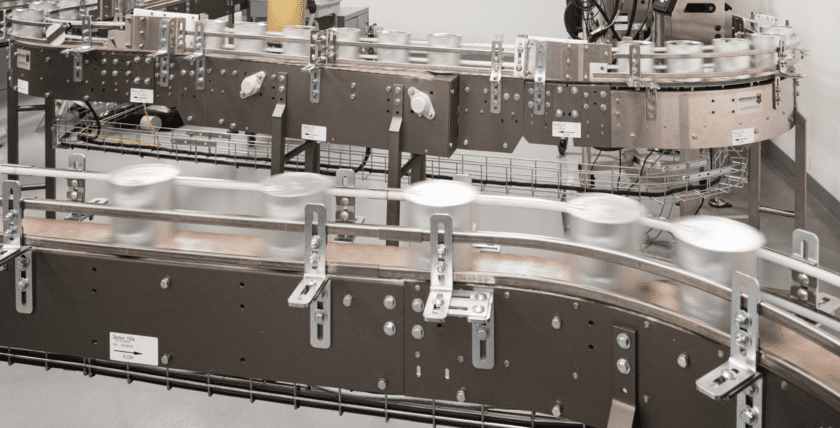

This plant expansion increased daily processing capacity and allowed DFA to recover water via improvements to the plant’s separation processes. Membrane filtration improves the energy efficiency of their drying operations, and the recovered water reduces water usage during process cleaning.

Our team designed the layout around the existing equipment, avoiding higher installation costs. DFA worked with our engineers, designers, and construction managers to plan and implement process improvements within the project budget and time constraints. As a result, we designed an upgraded HTST, larger and more efficient centrifugal separator, reverse osmosis membrane filtration for improved skim removal efficiency and water recovery as well as water storage and distribution systems.

2019

$7 million

Skanska