Projects

Process optimization adds $208 million in revenue

Confidential, USA

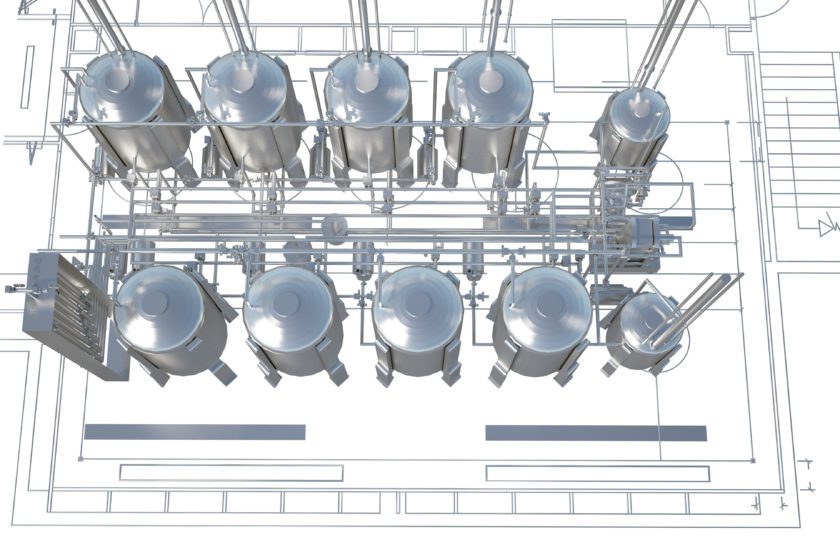

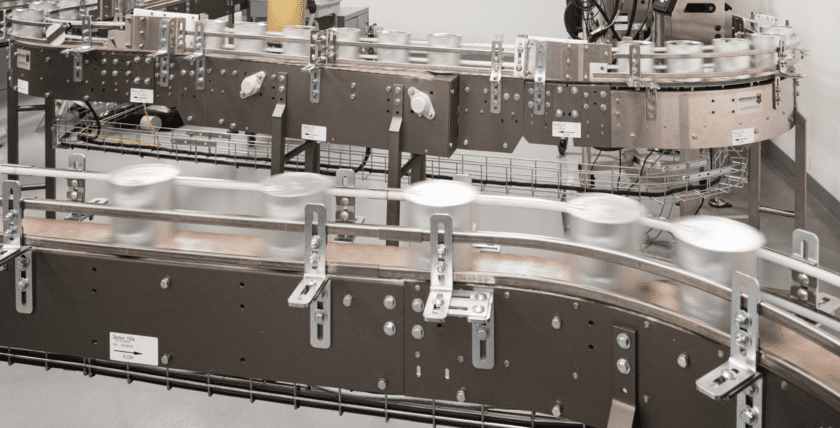

Manufacturing Process Improvements

A confidential international cosmetics manufacturer was considering building a new facility due to increased product demand. After initial consultation, Salas O’Brien proposed auditing the entire process from raw material to finished product, ensuring the most effective solution before embarking on such a substantial capital project. Our comprehensive evaluation identified process improvements within their current facility, resulting in an astounding $170 million in capital savings.

We collaborated with the client by analyzing the product and facility audit and presenting them with various process improvements, including enhanced cleaning effectiveness through new equipment integrations, reduced cycle times throughout the manufacturing process, and improved final product packaging. As a result, throughput increased by $208 million and eliminated the need for a new facility. This process improvement saved the company money and increased production by 81,000 jars per week, enabling them to meet demand three years earlier.

2021

$200 million