Projects

Engineering innovative aluminum casting facility

Hubbard, OH, USA

Billet/Ingot Casting Facility

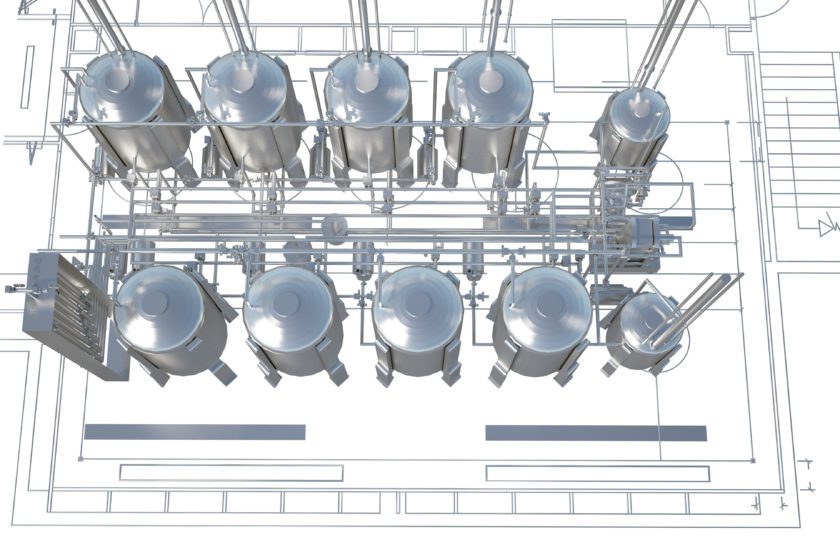

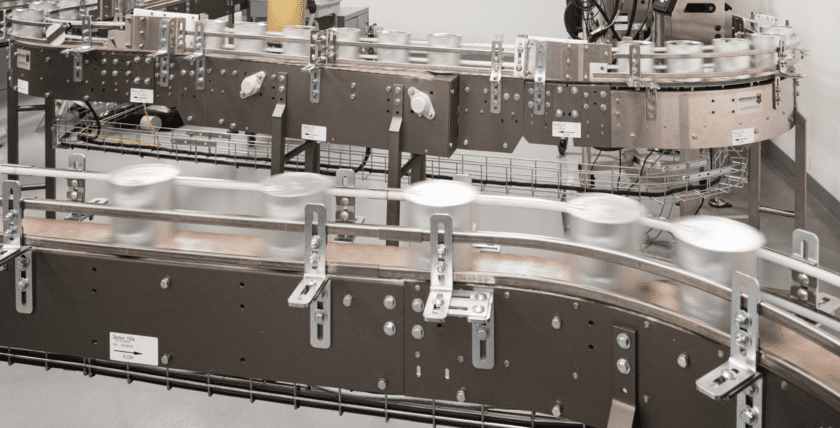

Salas O’Brien partnered with Ellwood Aluminum to provide engineering design and onsite construction management for a new aluminum casting production facility. The project included a 5,000-square-foot main office building, two motor control center buildings, a mold shop, and specialized equipment design such as melter and holder furnaces, baghouse, magnetic stirrer below the melter and holder furnaces, charge and skimming car, two different 40-foot casting pits, homogenizer and cooling furnaces and an ingot saw.

Our team proved their expertise by providing architectural, civil, structural, mechanical, industrial process, electrical, and controls and automation engineering services. This collaboration results in a modern aluminum casting production facility that meets both the client’s objectives and exceeds industry standards.

2020

120,000 square feet

$70 million