Projects

Custom fill lines boost production capacity to meet demand

CONFIDENTIAL, WI, USA

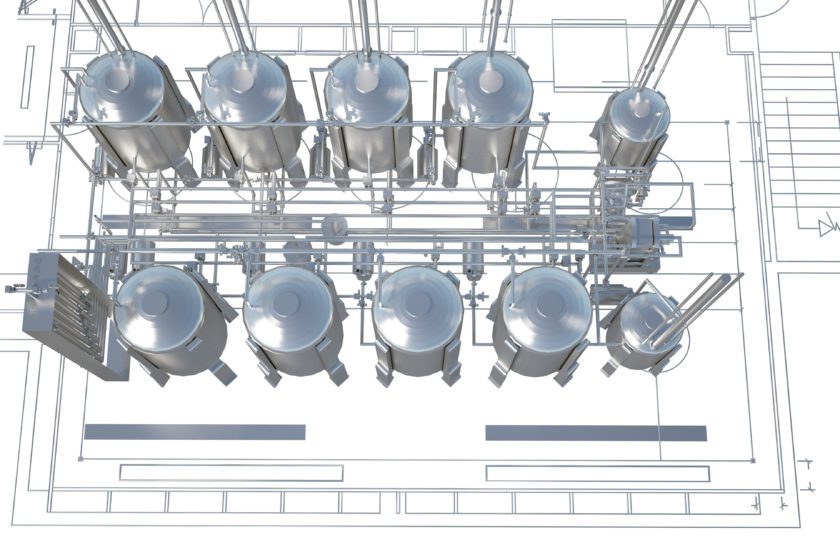

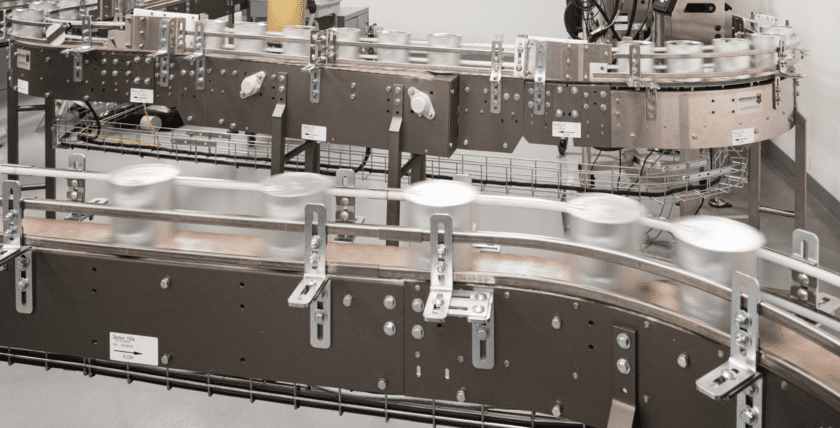

Automated Fill Lines

A prominent manufacturer in the carwash industry used manual fill lines to fill six container sizes for hundreds of products. However, the process was labor-intensive and inefficient, presenting ergonomic challenges for the workers involved. Salas O’Brien partnered with the client to develop a multi-phased plan to replace the manual fill lines with three fully automated lines. This approach minimized disruption to operations by keeping production running on the existing equipment until the final transition. Our work involved electrical and mechanical design, equipment procurement, complete system integration, construction management, and start-up support.

Our customized solution included depalletizing and transporting empty containers to the fillers and handling labeling, case packing, palletizing, and stretch wrapping. This significantly improved efficiency, enhanced working conditions for operators, and boosted production capacity to meet the growing demand.

Mechanical, Electrical, Process Engineering & Design, Digital & Automation, Industrial Construction Management

2024

$7.3 million

Eland Electric

Revolution Industrial Services