Projects

Ensuring sterile environment for injectable product

TERRE HAUTE, IN, USA

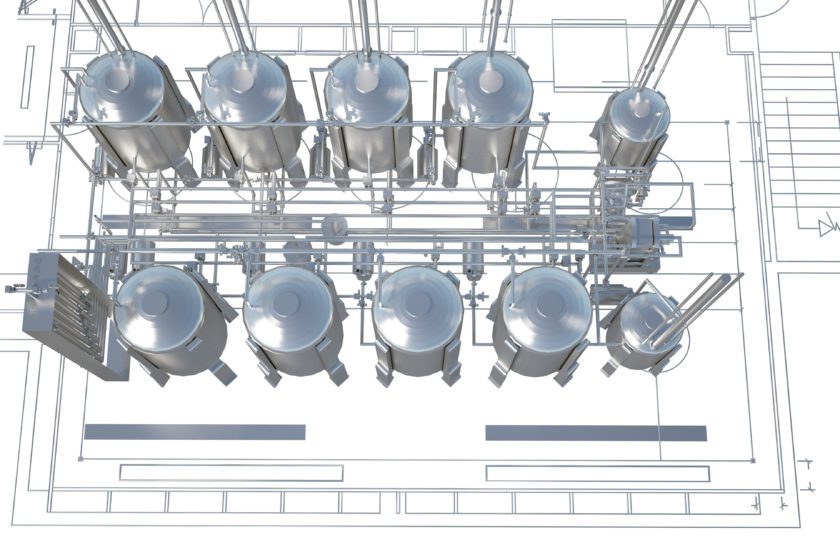

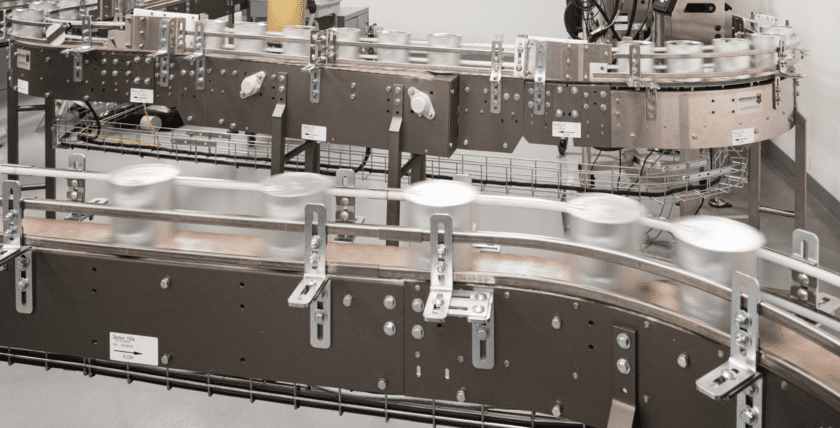

Aseptic Vial Filling Line

This project called for upgrading an aseptic area and powdered penicillin-based vial filling line for a sterile injectable product. The site and filling operation had major FDA issues and required a fast-track renovation to continue production with minimal downtime. The primary focus was verifying the sterilization of components and products and rebuilding the aseptic filling system.

Salas O’Brien reconfigured the line for optimum material flow, automated product sampling, and overall process control. In addition, we directed the site team in identifying non-compliant elements of the material handling and packing system. We also made engineering recommendations, assisted in budget and schedule development, provided detail design documents, and oversaw the implementation of changes that eventually brought the filling operation to compliance.

2020

$2.7 million