Projects

Virtual control system testing and optimization

Global

Standardized Controls with Digital Twins

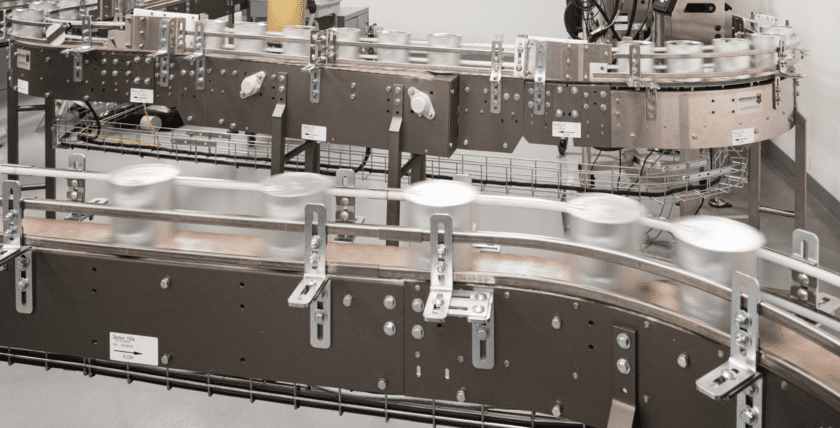

This client urgently sought a streamlined and standardized machine control methodology in global manufacturing. As a result, our team at Salas O’Brien developed a comprehensive approach that addresses the needs of multi-facility manufacturers, emphasizing the importance of process standardization to achieve product uniformity.

We used simulation-led design to enhance this approach and created digital twins based on approved layouts. We further integrated the PackML control methodology into individual unit machines and developed a standardized line control system, complete with panels, interfaces, and programming. A key aspect of our initiative establishing of a global support model tailored for both Original Equipment Manufacturers (OEMs) and End Users. By leveraging Emulate3D for control system validation and optimization, we aim to significantly reduce installation, start-up, and verification timelines, ultimately resulting in reduced engineering costs and faster operational readiness.

$3.5 million

Ongoing