Projects

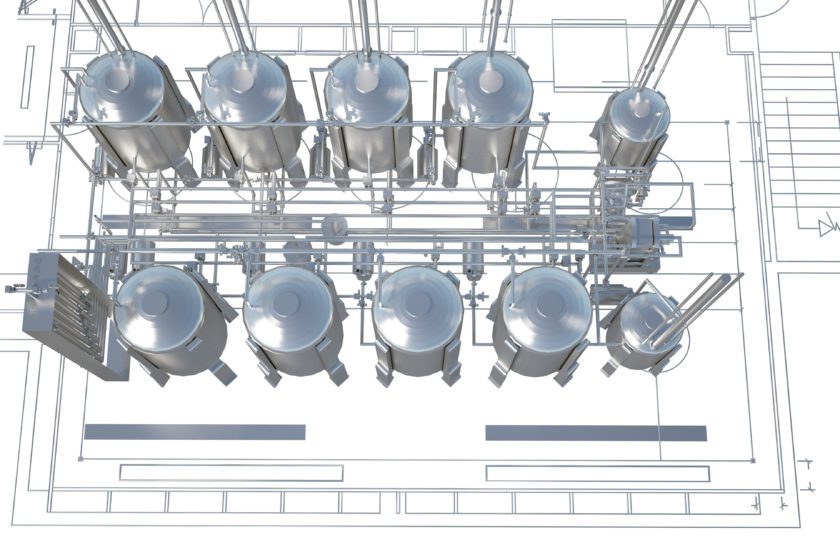

Chemical reactor integration and process design

Maumee, OH, USA

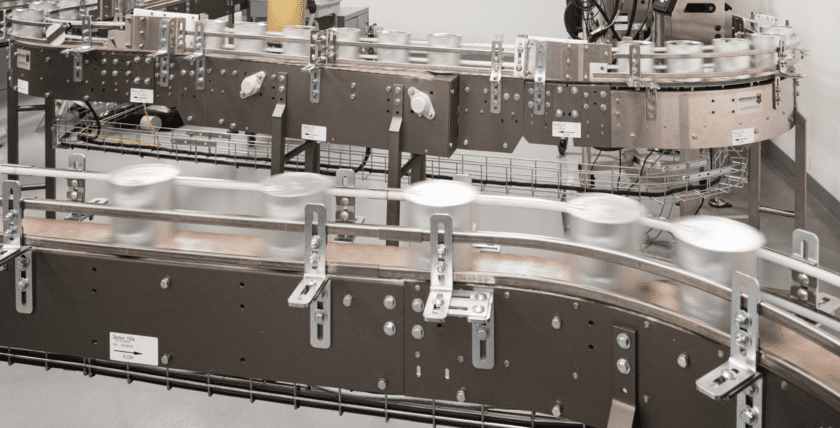

Dispenser Installation

Salas O’Brien partnered with Sun Chemical to develop 3D scanning of the Sun Chemical facility, to design a new chemical reactor and resin loading system, and tie them in with existing equipment and utilities.

We carefully considered space constraints, dusting control, and extensive client coordination. The installation of the new reactor included two heat exchangers, a loop water pump, and links to the plant’s hot water boiler and treated chilled water system. Manual bag dumping was available on the mezzanine alongside an automated pneumatic conveyor resin feed system with options for bulk bag unloading and palleted bag feeding. In addition, we designed an enclosure to house a roller conveyor, bulk bag unloading stand, bag slitter, and robotic arm. Water and ammonia were also supplied to the reactor, requiring a containment area, storage tank, truck receiving station, and tie points identified during a plant walk-down verified by our scanning technologies—the completed product transfers to four storage tanks, packaging areas, or truck loadout stations.

2020