Projects

Innovative new technology creates water mass balance and encourages energy reuse

Albany, Ga, usa

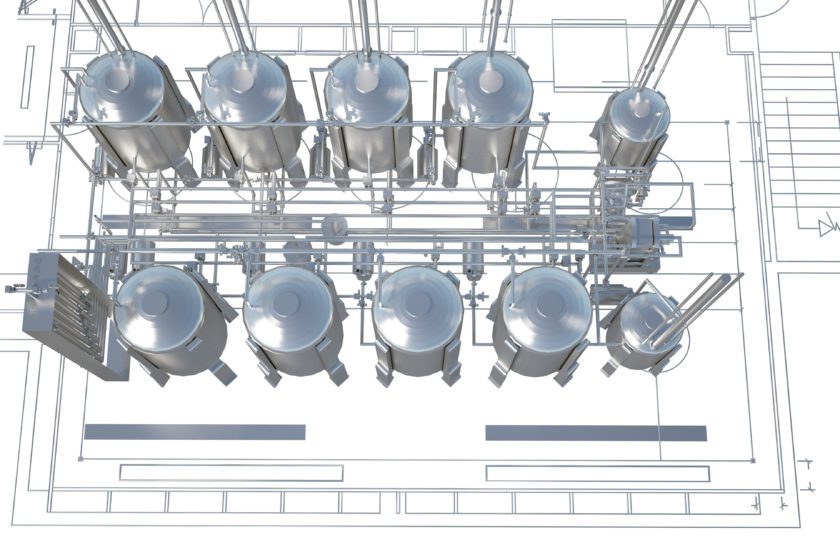

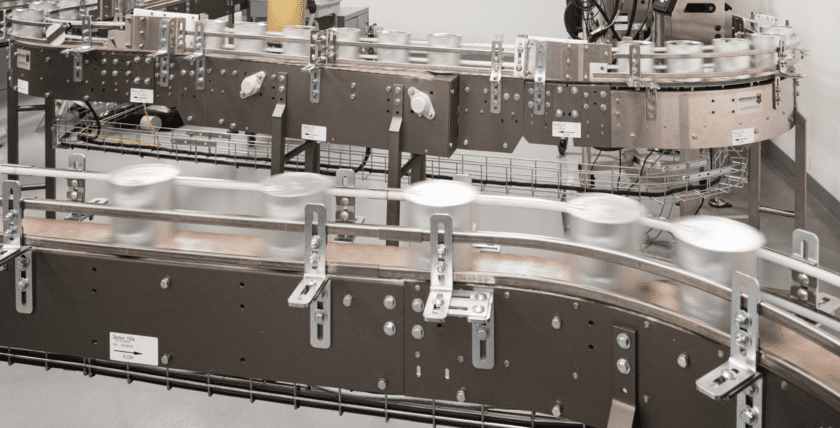

Filler and Pasteurizer Line Replacement

Salas O’Brien provided engineering design services to upgrade Molson Coors’ Filler and Pasteurizer Line. Our design resulted in a 20% reduction in power requirements for the water chiller by switching from continuous to punctual water cooling. This change also led to a 10% decrease in pumping requirements and reduced the load on the cooling tower. Our team’s process improvements optimized water quality at the pasteurizer, resulting in a more than 20% reduction in water treatment load. In addition, our designers and engineers eliminated the need for three different chemicals and their local pumps, thereby reducing operator risk and environmental costs associated with additional chemicals in the process. Drawing on our extensive experience, we designed and integrated a system with localized heat requirements, increasing the efficiency of the plate and frame heat exchanger and reducing steam usage by over 30%.

Process Engineering & Design, Facility Design, Operations & Maintenance, Structural, Sustainability

2025

$18 million

25,000 square feet

Krones