Projects

Digital twin simulation verifies requirements for enhancing productivity

Cincinnati, OH, USA

Digital Twin Simulation

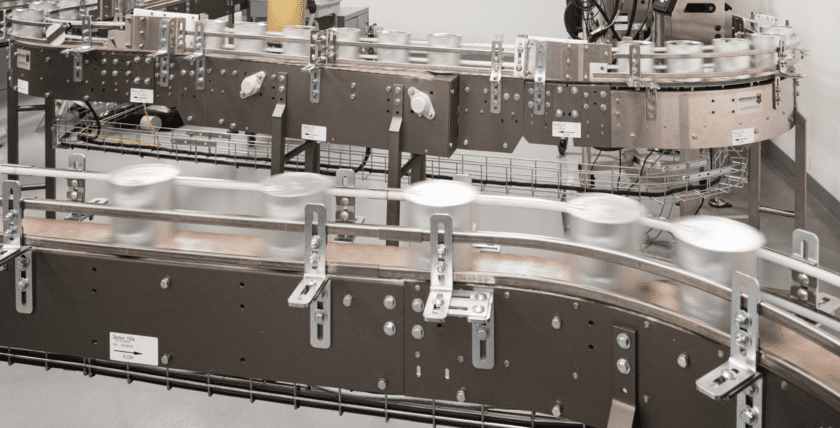

Salas O’Brien provided digital and engineering services to create a simulation model for a prominent industrial client’s client’s facility. The project goal was to allow the company to test planned process upgrades and implementations across key scenarios and identify gaps in existing planning. Additionally, created a flexible and adaptable model for future scenario testing. Our team successfully delivered an intuitive model with reusable and scalable components, which enables site-specific changes while still serving business objectives. The simulation covers bulk liquid receiving, tank farm storage, blending, buffering, packaging, and shipping. A graphical representation of these processes was critical for the client to visualize changes in real-time and obtain simulated data. Our team then validated the simulation to ensure a successful result that exceeded expectations and efficiencies.