Merger

PCI has joined Salas O'Brien

PCI, a valued supplier of engineering services to the national power and industrial markets, is now part of Salas O’Brien.

ABOUT PCI PCI MARKETS PCI SERVICES PCI HISTORY

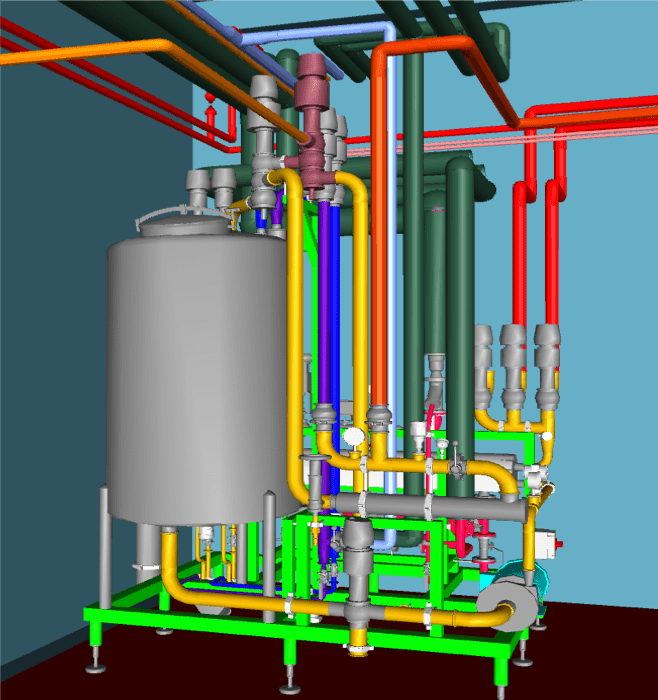

The PCI team enhances Salas O’Brien’s experience in important markets including pharmaceuticals, food and beverage, chemicals, and other industrial applications.

About PCI

PCI was founded in 1972 in Evansville, Indiana, a multidiscipline design firm born out of a construction company, now celebrating 50 years of service.

The team grew from a small number of engineers to nearly 100, today. The team specializes in electrical, mechanical, process, structural, and architecture. PCI merged with Salas O’Brien in 2021, extending its service offerings and expertise. PCI, a Salas O’Brien Company continues to be committed to Evansville, proud of its 50-year heritage in the community.

PCI Markets

Since 1972, PCI has been a valued supplier of design services to the national power and industrial markets. Our people develop well-planned solutions for our customer’s capital projects and maintenance needs, and we have an extensive portfolio in:

- Chemical, Plastics, Oil, and Gas

- Utilities

- Manufacturing

- Metals

- Pharmaceuticals

- Food & Beverage

- Commercial

PCI Services

Delivery Methods

Our EPC and Design-Build methods offer:

- Reduced risk

- Single point of responsibility for entire project

- Price certainty for defined scopes of work

- Less required customer coordination and project management making it a good option for customers with limited resources

- Speed of delivery

- Value-added design and construction synergies

Traditional Design-Bid-Build Delivery

When you want a partner to develop a solution and design your project to obtain construction bids, need assistance with obtaining and evaluating construction bids, and need administration services during construction to assure construction meets the intent of the design, look to PCI. We have all of the project management and primary design disciplines in-house to provide the services and support your project requirements and needs.

Full-wrap Delivery Methods

Along with project partners, PCI can offer full-wrap EPC/EPCM/DB for the power, industrial, and commercial markets. We’ve built our business by providing our customers with solutions that are tailored to their specific project needs and goals. One of our key differentiators is our ability to execute any project utilizing resources for all types of delivery methods.

PCI History

Charles Braun Sr. founded Industrial Contractors Inc. in 1964 as a general and mechanical contracting company. In 1972, Professional Consultants Inc. was formed as an affiliate engineering and architecture company to support Industrial Contractors with their projects. Over the years, Professional Consultants began to provide design services directly to local and regional clients and became better known as PCI.

In 2021, PCI merged with Salas O’Brien, creating a firm of 51 offices with more than 1,300 team members and more than 330 registered professionals with extensive experience in multiple markets in more than 16 disciplines.

Nearly 60 years since our inception, our strengths lie in a wide range of industries, and our enhanced expertise and international resources strengthen our ability to provide the best value customized solutions that support the success of our clients.