News & Insights

Engineering upgrades to Space Launch Complex 41 to support the ULA Vulcan Launch

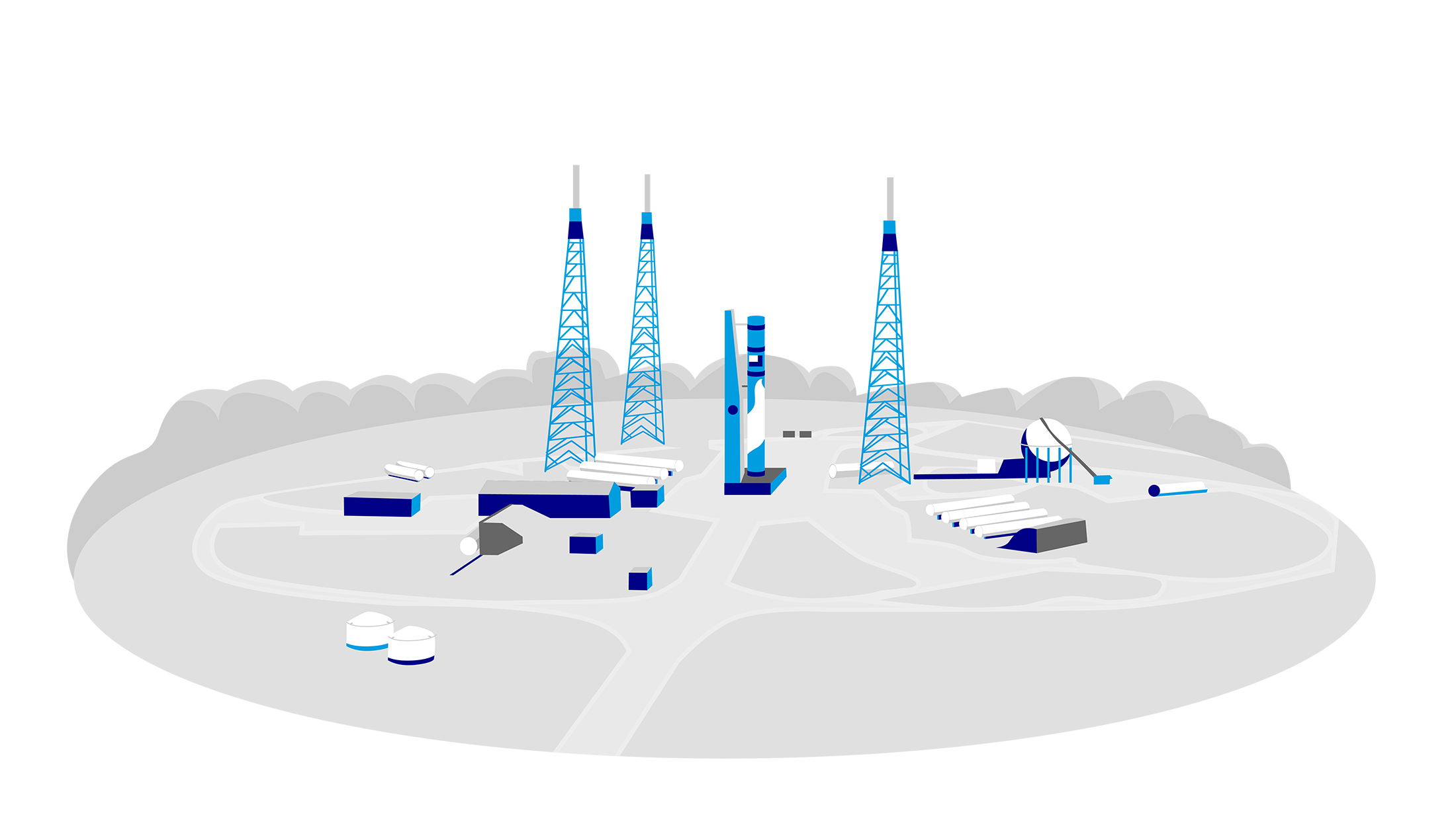

Salas O’Brien’s experts brought new solutions to the challenging issues surrounding the ULA Vulcan launch at Space Launch Complex 41 at Kennedy Space Center.

The Vulcan Centaur is the next-generation, all American rocket system by United Launch Alliance (ULA). It replaces the aging and storied technology of the Atlas V and Delta IV launch vehicles—which are being retired—launching satellites into different orbits for customers like NASA and Department of Defense.

Salas O’Brien provided comprehensive engineering services for the upgrades to Space Launch Complex 41 at Kennedy Space Center to accommodate the larger rocket and the new fuels. This article shares the challenges overcome to make the transition contributing to the promise of affordable space transport.

What is different about the new Vulcan rocket?

ULA’s Vulcan Centaur rocket is many steps forward from the previous technology. It has:

Bigger Payload capacity. The Vulcan Centaur has a maximum liftoff thrust of 3.8 million pounds of thrust, provided by two Blue Origin BE4 main engines at 550,000 pounds each and up to six Northrop Grumman GEM 63XL solid rocket motors at 463,200 pounds each. The payload carries up to 56,000 pounds to low Earth orbit, 33,000 pounds to a geo-transfer orbit, and 16,000 pounds to geostationary orbit. The rocket has greater capability than any currently available single-core launch vehicle.

Recoverable components. The Vulcan Centaur is designed for SMART (Sensible Modular Autonomous Return Technology) reuse. The primary booster separates after main engine cutoff (MECO) and are designed for recovery, bringing down the cost of spaceflight.

Better performing propellant. While Atlas V’s primary stage is fueled by Rocket Propellant (RP-1), similar to kerosene, and liquid oxygen (LO2), the new Vulcan BE-4 engines run on liquid natural gas (LNG), liquid hydrogen (LH2), and LO2. Research shows LNG fuel for space launch provides increased performance and lower cost and environmental impact compared to RP-1.

All American made components. From engine to payload fairings the Vulcan Centaur brings American technology to the forefront of the space industry.

What modifications were needed at Space Launch Complex 41 to accommodate the ULA Vulcan launch?

Fuel storage and distribution

The launch site required a new LNG cryogenic fuel fill, storage, and distribution system. It also required modifications to the existing LH2 and LO2 systems. For safety, Space Launch Complex 41 is divided into quadrants with clear separation of the fuels.

The design team developed process piping routing for the LNG, LH2 and LO2 cryogenic systems. Cryogenic fuels run from -200°F to -400°F which causes contraction in any pipe touched. Salas O’Brien performed thermal simulations on cryogenic vacuum jacketed and mechanically insulated vent pipes to design pipe supports to adhere to allowable stress and displacements caused by thermal contraction.

Another issue with cryogenic fuels is condensation. While the condensation on a cold drinking glass is formed from water vapor in the surrounding air, the condensation on an uninsulated cryogenic hydrogen fuel pipe is liquid oxygen. Droplets which could damage equipment or harm personnel. We routed un-insulated LH2 vent pipe away from walkways and critical equipment to prevent liquid oxygen from dripping onto equipment/areas with personnel. Where rerouting was not possible, we developed drip trays and protective covers.

Piping installations

To modify the existing launch complex, Salas O’Brien used trenchless piping to facilitate installation beneath and between existing systems. This greatly reduced risk of damage and removed the need to demolish and repair existing pavements and structures.

Salas O’Brien used horizontal directional drilling (HDD) for flexible pipes and conduits. Jack and bore installation methods allowed us to install a rigid casing pipe at a set grade and provided a protective encasement for the carrier pipe to pass beneath the existing launch structure. On this project, jack and bore operations had to be scheduled between rocket launches so they wouldn’t impact ULA’s launch manifest.

Vacuum jacketed piping for cryogenic fuels has to be precise in how it connects and routes around buildings. There is no margin to make costly adjustments in the field. Hensel Phelps provided 3D scanning of all the buildings and existing systems, and Salas O’Brien created a detailed 3D model in Creo Parametric and Revit to accurately develop each pipe route and adhere to strict slope requirements.

Fire protection and detection

To protect the fuel tank systems, Salas O’Brien developed and implemented deluge fire suppression systems, reinforced earthen berms and other physical safeguards. Our fire protection engineers designed the deluge suppression system with spray patterns to completely cover the entire 180 foot long 120,000-gallon hydrogen storage tank, truck fill stations, and other critical areas. Infrared flame detectors were also designed to provide optimal coverage to detect a fire early in these areas before catastrophic failure.

Fuel leaks in static distribution pipe and storage tanks are rare, however, trucks delivering liquid fuel create a vulnerable area at fill stations during fill operations. We minimized this risk by implementing NFPA hazard classification methods such as explosion proof electrical devices and deluge fire suppression systems that feature flame and heat detection capabilities.

Our engineers also provided extensive analysis of a new LNG spill basin to determine size and location. In the event of a complete storage tank failure, this basin is required to direct and collect LNG away where it could safely burn without damaging site critical infrastructure. This and studies for locating flare stacks for LH2 and LNG were part of the design of fire safety systems for the new site layout.

Acoustic Suppression Water System (ASWS)

Acoustic suppression systems help reduce the sound and vibration of a rocket launch. They do this by injecting large quantities of water into the exhaust plume at the area above the launch pad. This water is released just before the ignition of the engines and is delivered under high pressure to ensure uniform distribution and a blanket of steam to absorb the acoustic energy generated by the engines.

As part of the new ASWS water storage and distribution system, high pressure gaseous nitrogen (GN2) systems were designed to pressurize and actuate the water system flows. Salas O’Brien designed new high pressure (3,500 psig) nitrogen pipe routing, fittings, and tie in connections to existing facility systems. We provided initial pressure loss calculations and required flow rates and determined thrust forces caused by the fast-acting system activation sizing appropriate thrust blocks and supports to protect the piping from reaction forces.

The 30″ water pipe for ASWS was installed through jack and bore operation versus cutting and trenching the pad.

Site work and permitting

Prior to the modifications, Salas O’Brien developed the civil and sitework for each of the four tank installation areas. This included complete design drawings for re-grading and management/disposal of contaminated soil.

We developed storm water permit applications for the project area and obtained a St. Johns River Water Management District permit for construction. We assisted in the development of Storm Water Pollution Prevention Plans and environmental compliance determinations. Salas O’Brien developed the National Environmental Policy Act (NEPA) Environmental Assessment for the Vulcan Program that obtained a Finding of No Significant Impact (FONSI). We assisted in the development of plans to adhere to Land Use Controls requiring management of contaminated soils on-site.

We managed the permitting process by being extremely proactive and responsive with the agencies. Our drawings were highly detailed and comprehensive to minimize comments.

When did the new Vulcan rocket launch?

ULA first launched the Vulcan Centaur from the newly renovated Space Launch Complex 41 on January 8, 2024 with the New York Times calling the launch “flawless”.

The Salas O’Brien team provided the engineering that helped ULA to modernize and upgrade facilities to accommodate next-generation heavy-lift launch vehicles and has extensive experience with aerospace clients. Contact us to learn more at [email protected].

For media inquiries on this article, reach out to Stacy Lake, Director of Corporate Communications.

Jason Menzies, PE

Jason Menzies was the project manager for the modifications at Space Launch Complex 41. Jason leads a team of dedicated mechanical, aerospace, & fire protection engineers. With the Merritt Island team since 2007, Jason has led hundreds of mission critical projects. He has a Bachelor of Science in Mechanical Engineering from the University of Florida. Jason serves as a Senior Vice President at Salas O’Brien. Contact him at [email protected].

Jeff Longshore, PE

Jeff Longshore provided civil and environmental design for Space Launch Complex 41. Jeff leads teams of civil engineers and computer-aided designers. With the Merritt Island team since 2011, Jeff specializes in high-profile projects with challenging parameters. He has a Bachelor of Science in Civil Engineering from the University of Central Florida. Contact him at [email protected].