News & Insights

Beyond one-size-fits-all: customizing project delivery for industrial clients

Selecting the right delivery method is one of the key decisions project leaders must navigate in industrial project management. This article clarifies the delivery options at your disposal to help you find the best fit for your project's objectives, scope, and complexity.

Whether embarking on a complex manufacturing facility, a large-scale infrastructure redevelopment, or any process upgrade, the choice of delivery method can significantly impact a project’s outcome.

This article demystifies the various delivery options available, from the traditional Design-Bid-Build method to the more contemporary Engineer-Procure-Construct (EPC) method. We will explore the unique attributes of each method to align with a project’s goals, scope, and complexities.

What are the most common project delivery methods for industrial projects?

From standard facilities to highly specialized plants, industrial facilities have specialized demands for cost control, schedule efficiency, risk management, and technical performance. While there are many variations on project delivery methods, these three are the primary methods used in industrial manufacturing:

EPC (Engineer, Procure, Construct)

EPC is a form of contracting arrangement where the EPC contractor is given performance requirements then is responsible for all the activities from design, procurement, construction, to commissioning. At closeout, the EPC contractor hands over a working facility that’s ready to go. This approach is common for large-scale, complex projects.

Favored for

- Comprehensive solution. EPC offers a complete package that covers all aspects of project delivery from design through to construction and commissioning. This is particularly valuable for industrial projects that are complex, require high levels of technical expertise, and/or where time and cost efficiencies are critical.

- Risk management. The EPC contractor assumes much of the project risk, providing the project owner with a fixed cost for the project. This is appealing in industries where budget and schedule overruns can have significant financial implications.

Design-Build

This method integrates design and construction services under one contract with a single point of responsibility and aims to streamline project delivery through a unified workflow. At closeout, the

Favored for

- Streamlined process. By combining design and construction phases under a single contract, design-build allows for faster project completion, which is a critical factor in industrial projects that often operate under tight schedules.

- Cost savings. This method can reduce costs through efficiencies in the design and construction process, which is particularly important for industrial projects managing large capital budgets.

Design-Bid-Build

The most traditional project delivery method is where the owner manages the project directly, overseeing separate contracts for design and construction. The project is designed first, then put out to bid for construction.

Favored for

- Clear separation of roles and phases. This traditional approach with distinct design, bid, and build phases allows industrial project owners to have maximum control over each stage, making it easier to manage costs and quality.

- Competitive bidding. It enables competitive bidding for the construction phase, which can help to reduce costs, a significant consideration for large-scale industrial projects.

Variations on Design-Bid-Build

Design-bid-build comes in different variations with various levels of client engagement and ownership. Common terms used to describe these variations include EPCM (Engineering, Procurement, and Construction Management), CMA (Construction Management Agency) CM As-Agent, CMAR (Construction Management At-Risk). The exact definition and application of each of these terms can vary depending on the parties involved and the specific project. Rather than focusing on the terms, The Owner and Contractor should focus on the relationships, resources, expertise, and risks to best define the execution strategy for success.

Below is a sample list of Design-Bid-Build execution options in order of least client engagement to most client engagement. NOTE: For nearly all Design-Bid-Build options, a substantial amount of engineering is completed before procurement and construction commitments are made. For that reason, we have assumed that the Owner has hired an engineering firm and completed detailed engineering for each of the options below.

- The Owner awards one (1) contract for complete procurement, construction, commissioning and startup delivery of the project.

- The Owner self-performs critical procurement delivery and awards one (1) contract for the balance of procurement and construction delivery of the project. The Owner self-performs the bulk of commissioning and startup.

- The Owner self-performs the bulk of procurement delivery and holds all construction contracts. The Owner hires the contractor to act as the Owner’s agent to manage the procurement and construction delivery. The Owner may also hire the contractor to assist in the managing of commissioning and startup.

- The Owner self-performs the bulk of procurement delivery and management of construction. The Contractor provides technical consultation only during procurement and construction.

Variables that drive selection of a project delivery method

Multiple project delivery methods exist because differences in clients, project needs, and timelines necessitate flexibility. Here are some of the key drivers that can affect the selection of a delivery method:

Quality and safety

While quality and safety are often referenced as drivers in project delivery selection, it’s important to note that in industrial markets, these are non-negotiable standards. Regardless of the delivery method chosen, all projects must adhere to the highest levels of quality and safety. The differentiation lies in how each method approaches these standards and ensures these standards are met throughout the project lifecycle.

Relationship-based drivers

The nature of the relationship and level of engagement desired by the client play a significant role in selecting a project delivery method. Clients with a robust in-house team might prefer a method that allows for more direct control and oversight, such as Design-Bid-Build. In contrast, clients lacking in-house expertise or bandwidth may favor a more turnkey solution, like EPC where a single entity is responsible for most of the project’s aspects.

Questions to ask

- Is there an extensive client-side team with expertise and experience who desire a high degree of collaboration, or is the client taxed-out and needs to hand off to external expertise and project management skills?

- Is this a stand-alone project, or does it heavily integrate with existing operations?

- Does the Client have well developed and specific standards and methods critical to the project’s success? Or are the objectives and outcomes of the project more industry standard, and generally known.

Risk-based drivers

The allocation of risk is a cornerstone in the decision-making process for a project delivery method. Each method distributes risks differently among the parties involved, influencing the choice based on the client’s risk tolerance and the project’s complexity. Understanding who is best equipped to manage and mitigate the project’s inherent risks is crucial.

Questions to ask

- What risks are foreseen for the project?

- Who needs skin in the game?

- Which stakeholders will best manage the risk for this project?

Financial drivers

The financial aspect encompasses budget constraints, cost predictability, and the overall financial strategy for the project. Delivery methods like CMA and EP-GC offer a degree of cost certainty early in the project, which can be crucial for clients with tight budget constraints or those requiring firm cost commitments to secure financing.

Questions to ask

- How early does the project need to get to cost certainty?

- How significant is the project cost impact to the overall business

- Are there independent, industry standard cost metrics that can support project cost, or is the project truly unique and customized?

Schedule drivers

In a rapidly evolving market, the speed of project completion can be a critical factor. Delivery methods that integrate the design and construction phases, such as Design-Build and EPC, can significantly shorten the overall project timeline and offer a quicker path to operational readiness and ROI.

Questions to ask

- What are the consequences of project delays on the client’s operations and market positioning?

- How critical is the project timeline to achieving market goals and ROI?

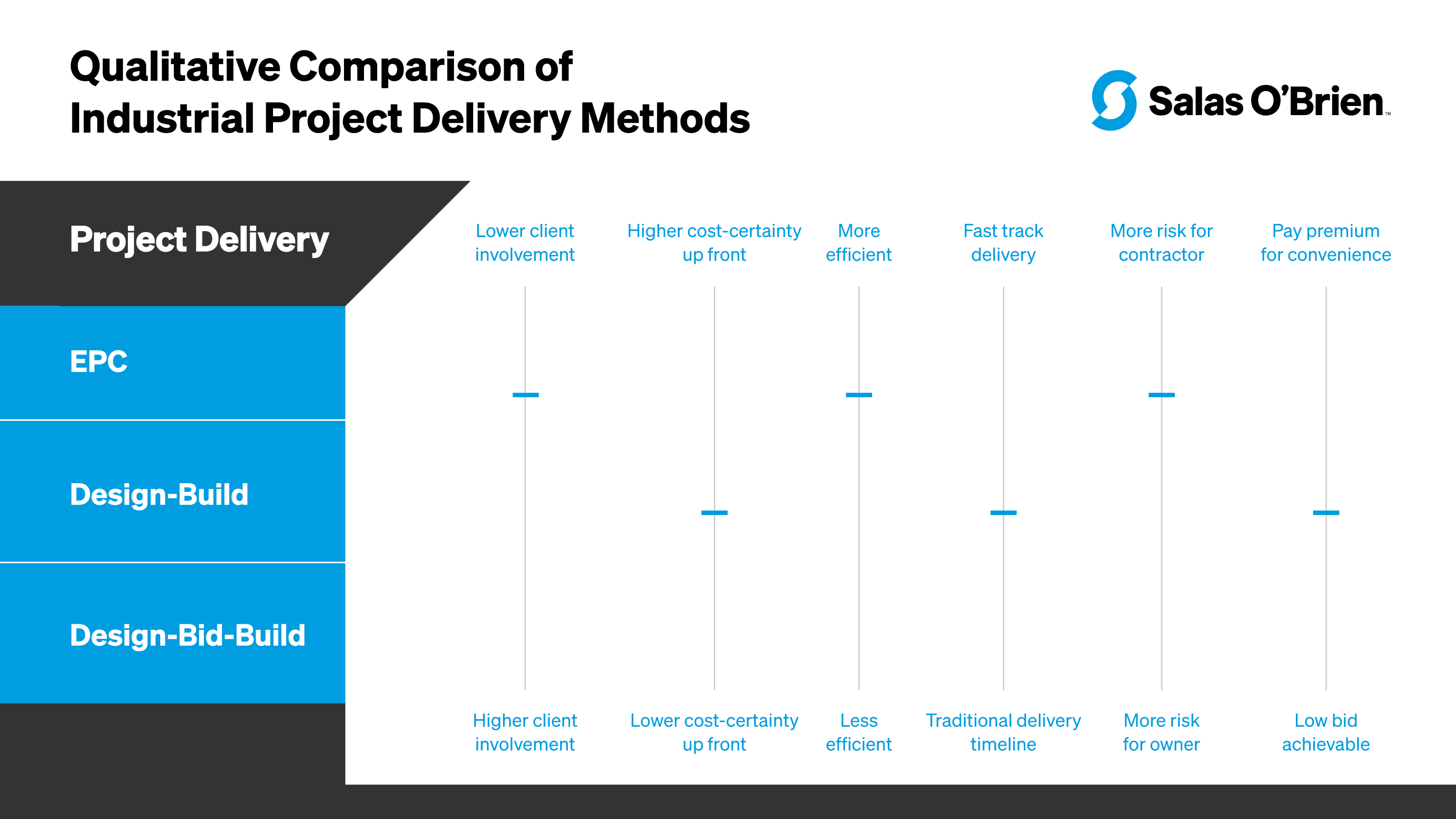

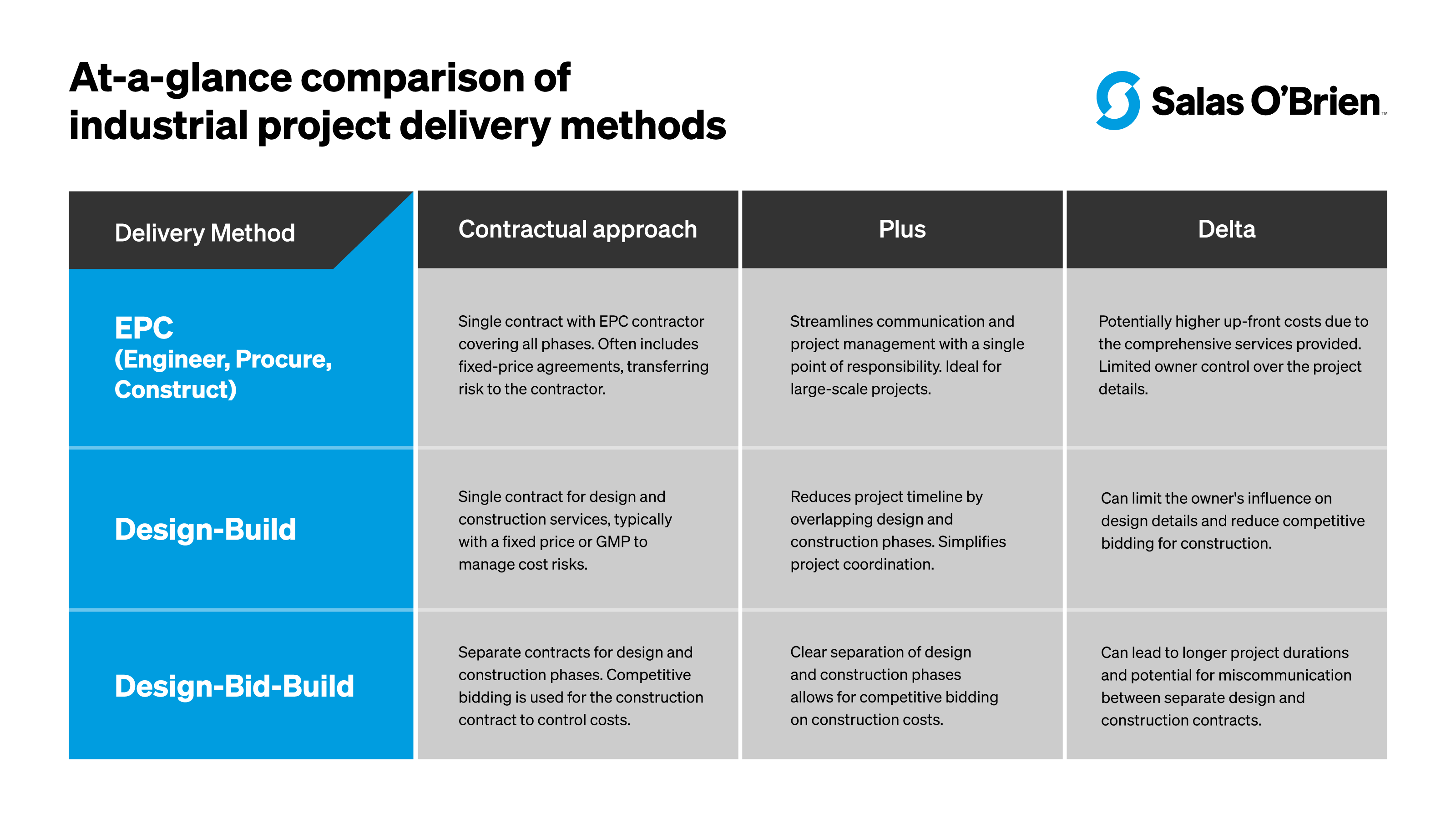

At-a-glance comparison of industrial project delivery methods

This matrix compares the most common types of project delivery methods. Each method has its unique advantages and challenges, making it suitable for different types of projects within the industrial manufacturing sector.

How Salas O’Brien can help

Salas O’Brien offers comprehensive project delivery solutions and expert guidance throughout the lifecycle of industrial manufacturing projects. We specialize in adapting to the unique needs of each client, whether they come with a wealth of experience or are navigating the complexities of project delivery for the first time.

We are here to demystify the options and guide you through choosing the most suitable project delivery method for your specific needs. Our goal is to empower your project with the right expertise, strategies, and technologies to ensure success from inception to completion. Reach out to one of our contributors below to talk about your project.

For media inquiries on this article, reach out to Stacy Lake, Director of Corporate Communications

Adam Benjey, PE

Adam Benjey has over 20 years of capital project management, construction management, and design experience for manufacturing clients in highly regulated industries. Adam consistently establishes client trust and confidence by championing his clients’ business objectives, delivering technical excellence, and managing projects with transparency, flexibility, and predictability. Adam serves as a Senior Vice President for Salas O’Brien. Contact him at [email protected].

Andrew Lee, PE

Andrew Lee has over 20 years of experience in serving key client relationships in industrial manufacturing, including pharmaceuticals, food and beverage, chemicals, metals, and consumer products. His expertise is at the intersection of commercial needs, technical expertise, and project management to deliver excellent results in a rapidly changing marketplace. Andrew serves as a Principal at Salas O’Brien. Contact him at [email protected].

Greg O'Brien

Greg O’Brien provides engineering consulting to industrial, manufacturing, and commercial clients. He directs the project team in Salas O’Brien’s Evansville office that provides project budgets and cost estimates, assures code compliance and quality control, and manages the construction bidding process and contracts. Greg serves as a Principal at Salas O’Brien. Contact him at [email protected]