News & Insights

Enhancing performance through building envelope consulting and testing

The integrity of a building's envelope is pivotal to its overall performance. Through expert consulting and advanced testing, building owners can unlock energy efficiency, durability, and comfort enhancements, setting new benchmarks for high performance.

The building envelope plays a crucial role in determining a building’s energy consumption. Consider this scenario: If 200,000 cubic feet of air per minute of conditioned air is saved, imagine the amount of energy that can be conserved. On the other hand, if the same amount of air is lost due to a leaky envelope, the building would need to expend energy every minute to heat or cool that air.

With the critical role a building envelope plays in energy conservation, the stakes are high, elevating building envelope consulting from a mere option to a necessity in the modern construction and maintenance landscape.

What makes up the building envelope?

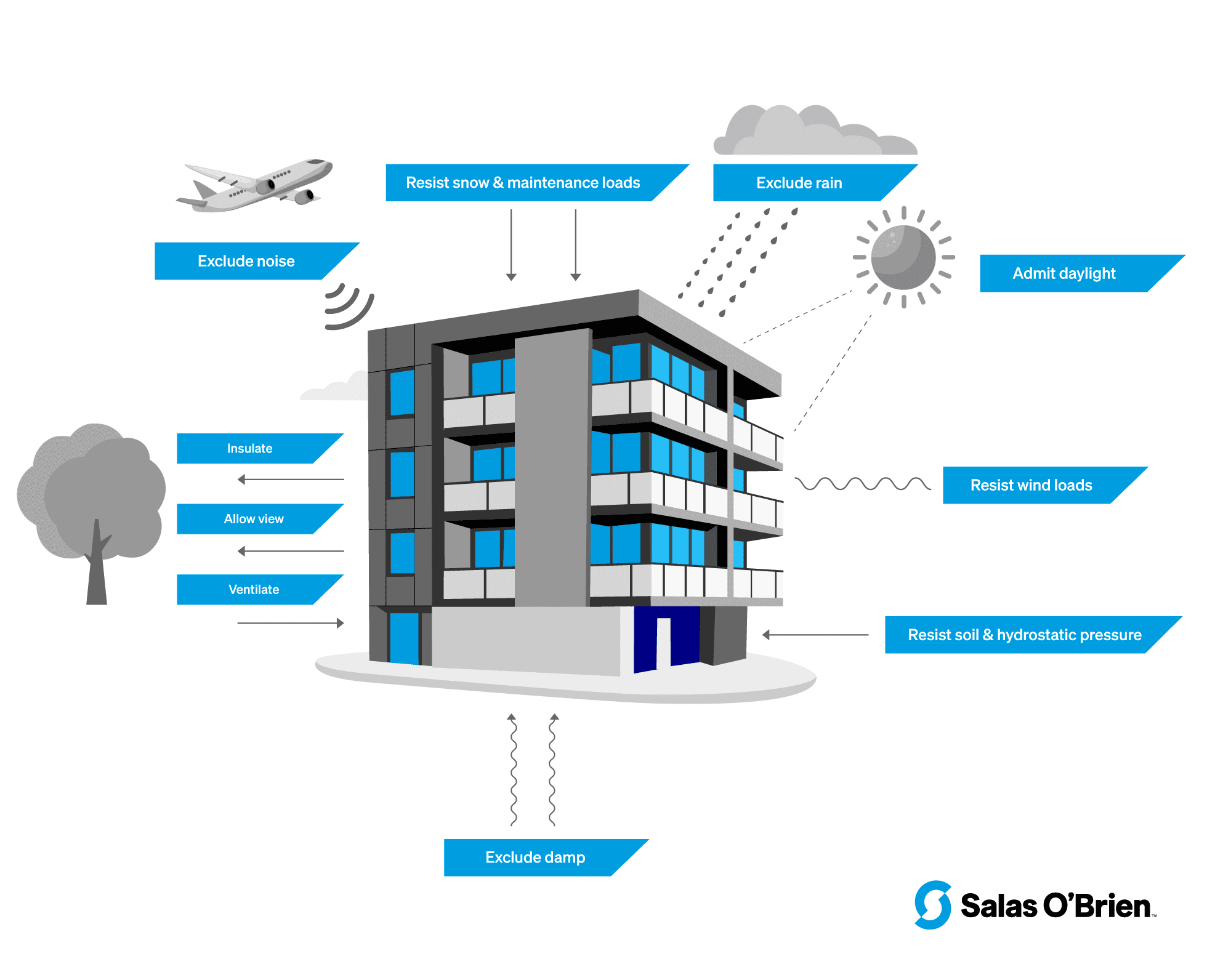

A building envelope is a physical barrier, including the walls, roof, foundation, windows, and doors, between the interior and exterior of a building designed to protect against external elements and manage the indoor environment.

From highly insulated wall systems and energy-efficient windows to permeable membranes that block liquid water but prevent moisture buildup by allowing water vapor through, this complex interplay of materials and design strategies ensures the building envelope can withstand the rigors of its environment while maintaining a healthy, comfortable, and sustainable interior space.

What’s put the increased focus on building envelopes recently?

A convergence of factors has put building envelopes in the spotlight. Here’s a look at the dynamics:

- Changing building codes. Building codes across North America increasingly demand higher standards for envelope performance in response to federal and municipal demands for more energy-efficient buildings.

- Next efficiency frontier. With significant gains in the energy efficiency of lighting, equipment, and appliances, the focus has naturally shifted to the building envelope. The building envelope provides an opportunity to embed energy efficiency from the outset or improve performance through retrofits. In many cases, energy savings can increase over 25%, especially in older buildings which were designed and constructed to simpler standards.

- Prioritizing indoor air quality. The building envelope controls air exchange and impacts temperature, humidity, and pollutant levels. A well-designed envelope paired with well-designed mechanical systems ensures a healthier indoor environment, simultaneously meeting sustainability goals and occupant health demands.

- Minimizing risk in a changing climate. There’s an increasing focus on the resilience of buildings in the face of extreme weather and fluctuating temperatures, which can test the limits of traditional building designs. A well-designed building envelope reduces energy use and emissions and minimizes risk by enhancing the building’s ability to withstand environmental stressors.

- High-profile failures. Negative news and tenant and social media responses to recent high-profile structural failures, water intrusion, and indoor air quality issues due to compromised building envelopes have made building owners more aware of the need to prevent issues and resolve in a timely manner when issues arise.

- Embracing voluntary standards for maximum impact. More owner-developers are choosing green certifications like Passive House, recognizing their minimal cost impact yet substantial benefits. This trend is particularly notable in office and mixed-use buildings where the building envelope’s high performance and efficiency gains align perfectly with economic and environmental goals.

This combination of influences, among many others, has amplified the need for specialized building envelope consulting and testing. The return on investment is profound for sustainability, durability, occupant comfort, and—the big win—energy savings.

Maintaining building enclosure integrity with Building Envelope Commissioning

Building Envelope Commissioning (BECx) is a thorough process to ensure a building’s envelope meets the project’s requirements and aligns with the owner’s vision and operational needs. While sharing similarities with the commissioning of mechanical, electrical, and plumbing (MEP) systems, BECx focuses on the unique aspects of the building’s enclosure and runs from early in the design phase through occupancy. Retro-BECx can also be implemented when maintaining or implementing capital repairs.

Here is a breakdown of the process and its benefits:

Developing project requirements. BECx begins by collaborating closely with the owner to define the owner’s project requirements (OPR). This foundational step ensures that the commissioning process is tailored to achieve the project’s specific goals from energy efficiency to durability.

Design reviews. Reviewing the envelope details at multiple stages of design allows for optimization so the envelope can be constructed easily and correctly. The envelope design is just as important as its construction. Design reviews are the first and best opportunity to detect envelope weaknesses.

Comprehensive communication and documentation. The management of communication among all stakeholders is central to BECx. The process involves creating a detailed commissioning plan that includes basis of design (BOD), schematic design (SD), design development (DD), and construction documents (CD). After the design is published, shop drawings and submittal reviews are incorporated, and subsequently pre-install meetings, mock-ups, and/or first-of-kind installations occur where project teams will work together to troubleshoot issues that arise on the job site. The BECx plan is a roadmap with checklists and protocols to guide the project team in how to communicate and accomplish the design intent through the contractors’ means and methods. It aligns the team with the owner’s vision, facilitating a transparent and efficient workflow.

Adaptability and quality assurance. Recognizing that project goals may evolve, the commissioning plan is a living document adaptable to the owner’s changing needs. A significant phase of BECx is determining what level of quality assurance to commit to and where to focus efforts on the mock-up, inspection, and testing of envelope components to identify any constructability issues, verify performance, and ensure the construction meets both the design documents and the OPR.

Ongoing collaboration and oversight. The BECx process requires a close relationship with the general contractor (GC) and trade partners, regular attendance on site and during tests, and participation in construction meetings to address and resolve any action items promptly. Whether it’s evaluating substitute materials, reinspecting a resolved issue, or participating in bid meetings, the commissioning team reviews envelope components to ensure they meet the project’s standards and work cohesively.

Final documentation and training. As the project progresses, BECx facilitates the training of operations and maintenance staff and compiles comprehensive systems manuals and warranties. These resources provide detailed information on the maintenance and repair of envelope components, ensuring proper resolutions and long-term building performance.

Integration with building information modeling (BIM). A forward-looking aspect of BECx is linking commissioning data to the building information model (BIM) to create an “As-Constructed” model. This integration offers valuable insights for maintenance and future renovations, embedding the commissioning information for easy reference. RFIs, issues, or other discrepancies from the original design can be documented and linked to the model for future reference.

Building envelope commissioning is not just about oversight; it’s about ensuring the owner’s investment is protected and optimized for years to come.

Common building envelope issues in design and construction

Protecting from oversights is essential because the building envelope works as an integrated system. This section sheds light on some common building envelope misses through real-world examples encountered in new construction.

Incomplete details on how things go together

A case from a college residential hall highlights the issues with incomplete documentation. During construction, fog testing revealed large gaps in the air barrier where the building’s walls met the roof. Inadequate plans for connecting these elements and uninformed decision-making during the construction process meant this issue was not discovered until testing. Addressing this oversight before substantial completion fixed a potential structural flaw and led to significant energy savings by preventing warm, conditioned air from escaping during colder months. Building envelope consultants can provide design reviews to catch incomplete documentation before it becomes problematic.

Design reviews out of sequence with design

Out-of-sequence design reviews can disrupt project timelines and inflate costs. When design reviews lag behind the actual design process, resolving discrepancies becomes challenging. These discrepancies are often addressed through requests for information (RFIs) and change orders, which often add cost to the project budget and are time-consuming. Projects without effective design reviews have resulted in hundreds of RFIs and change orders. This situation leads to the inevitable question, “Why wasn’t this caught earlier?” To avoid these expensive oversights, having someone on the team focused on efficient and timely documentation and review processes for the building envelope is essential.

Use of inappropriate products during value engineering (VE) processes

VE aims to optimize the project’s value by saving costs where possible. However, when it results in the selection of inferior materials or systems, the consequences can be detrimental. These subpar choices may initially go unnoticed, but over time, their inability to perform as required becomes glaringly apparent as systems fail. This often happens on relatively large-scale square or linear footage material orders for components less likely to be initially perceived by the building occupants such as roofing membranes, insulation, waterproofing, air barriers, and sealants. Having a building envelope consultant review substitutions can save many headaches as the building ages.

Delayed testing leads to costly setbacks

Ideally, critical performance-driving components should be tested before superficial finishes conceal them. In one case where testing was postponed, a mid-rise building faced a major issue: every window failed testing due to a manufacturer defect. As a result, there were significant delays while waiting for remediated windows, and installing the remediated windows necessitated the expensive removal and reinstallation of finishes. The company incurred additional costs due to missing the occupancy date, including temporary office space for employees. A building envelope commissioning plan could have sequenced testing to discover the defect during a pre-construction mock-up review, preventing installation of faulty windows.

Misalignment in the field

Field observation by a building envelope consultant can uncover minor errors that can lead to significant expenses if unaddressed. On one site visit, the building envelope consultant noticed the placement of the drip edge, the metal coping installed along the roof’s perimeter. Its purpose is to safeguard the façade by channeling water away from the building and toward the ground. However, a misalignment in installation was going to direct water onto the façade for a future of rapid staining, leaks, and premature aging. Having a building envelope consultant look for these kinds of details in the field results in protections for an investment.

Damage during installation

On a new library, an electronic leak detection (ELD) scan of the roof identified hundreds of pinholes in a brand-new single-ply roof membrane. It was determined that the pinholes were caused by metal roof installers using the single-ply roof membrane area for staging and cutting sheet metal flashings (with sparks burning holes in the plastic and scrap metal falling onto the roof where a combination of foot traffic and sharp objects impacted the roof surface). The pinholes were not discovered during the roof manufacturer’s final inspection due to their relatively small size and restricted visibility from the white roof’s solar reflectivity. Yet, if not found by the ELD scanner, the pinholes would’ve led to a leaky roof and, eventually, a costly roof replacement repair. Because they were found before turnover, the contractor made corrections to the damaged roof membrane without costing the owner additional money.

Building envelope remediation for existing buildings

For existing buildings, the durability and performance of the building envelope are crucial indicators of the structure’s overall health. Over time, environmental exposure, material degradation, and mechanical wear can compromise the envelope’s integrity, leading to problems such as water infiltration and air leakage. These issues affect the building’s energy efficiency and comfort and pose significant risks to structural safety and indoor air quality.

For instance, excessive ice buildup on the exterior can indicate poor insulation or air leakage, suggesting heat is escaping and causing ice to form as warm indoor air meets cold outside air. Similarly, residents complaining of smoke odors from adjacent units could signal gaps allowing air—and smoke—to travel between spaces. Persistent dampness or mold growth inside the building points to water infiltration due to compromised seals or inadequate drainage systems, allowing moisture to penetrate and accumulate within the structure. Not only does this affect the building’s air quality and the health of its occupants, but it can also lead to structural damage if left unaddressed.

Building envelope consultants play a vital role in diagnosing these problems. Through comprehensive assessments, they identify the specific components of the envelope that are failing—be it sealants, flashing, cladding, or insulation systems—and understand the underlying causes of these failures. The investigation may reveal issues ranging from simple wear and tear to more complex problems like design flaws or inadequate maintenance.

The approach to remediation varies based on the extent of the damage and its impact on the building. In some cases, targeted repairs may suffice to address localized issues, effectively sealing leaks and restoring protection against moisture and air intrusion. These repairs can often be a cost-effective way to extend the lifespan of the building envelope without extensive interventions.

However, more substantial measures may be necessary when the damage is widespread or the envelope’s performance is severely compromised, which could involve large-scale replacements of components or even a comprehensive overhaul of the envelope system. While more expensive, such interventions are essential for ensuring the building’s long-term viability and safety. They also provide an opportunity to upgrade the envelope with newer, more efficient materials and technologies, enhancing the building’s overall performance and sustainability.

Advanced testing methods for optimal performance

Whether in construction or remediation, a key asset that building envelope engineers bring to the project is various testing methods. These are some of the most common:

- Air Infiltration Testing (ASTM E783) This test measures the amount of air leakage through a building’s envelope. A chamber is attached to a section of the wall, and air is forced through the chamber to obtain a numeric value representing the air permeability of the envelope.

- Water Penetration Testing (ASTM E1105, ASTM E2128, AAMA 501.2, AAMA 502, ASTM C1601, ASTM C1715, D5957) These standards are employed to assess the water resistance of the building envelope. Water is applied to the exterior of the building under controlled conditions to identify any leak paths or points of entry through the envelope.

- Theatrical Fog Testing (ASTM E1186) Utilized to detect air leakage paths visually, fog testing involves generating a non-toxic fog within the building or a specific envelope component. Observers then identify where the fog escapes, pinpointing air leakage sites.

- Thermal-Infrared Thermography (ASTM C1060, E1186) This non-invasive imaging technique uses thermal-infrared cameras to detect temperature variations on the building’s surface that are indicative of anomalies such as missing insulation, thermal bridging, or moisture accumulation.

- Blower Door Testing (ASTM E779, E1827, E3158) Conducted to evaluate the overall airtightness of a building, blower door tests measure the volume of air leakage. This test involves using a powerful fan to depressurize or pressurize the building and quantify the air infiltration rate.

- Roof Scan for Moisture-Related Thermal Anomalies (ASTM C1153) This test uses thermal imaging to scan roofing systems for potential moisture, damaged insulation, and other sources of moisture related to thermal anomalies. By identifying areas of temperature variation, building envelope experts can analyze the results and pinpoint locations where moisture may be trapped within the roof system with ramifications like deterioration of roof adhesives and substrate boards.

- Roof and Waterproofing Moisture Surveys (ASTM D7877, ASTM D7954) This test uses nondestructive electrical impedance scanners to locate moisture and evaluate the comparative moisture content within insulated low-slope roofing and waterproofing systems.

- Adhesion/Cohesion Testing and Profile Sampling of Installed Sealants (ASTM C1401 and ASTM C1521) This test is a simple yet effective way of gauging various parameters that relate to the quality of sealant installation workmanship and contribute to sealant performance throughout a project. The test checks sealant bead size and configuration, joint movement, quality of workmanship, the quality of the adhesive bond, and the quality of the sealant material.

- Pull-Off or Uplift Strength of Installed Coatings or Adhesives (ASTM D4541, D7234, and others) These test methods cover a procedure for evaluating the pull-off strength (or adhesion) of a coating system from its substrate.

- Structural Performance Testing for Fenestration (ASTM E330) This test method is a standard procedure for determining structural performance under uniform static air pressure difference. This typically is intended to represent the effects of a wind load on exterior building surface elements.

Each testing method provides valuable insights into a building’s envelope performance. Together, they form a comprehensive approach to ensuring a structure’s durability, efficiency, and comfort; safeguard against potential problems; and contribute to the building’s overall sustainability.

Inside Salas O’Brien’s Daytona Beach materials testing lab

Holding prestigious accreditations such as ISO 17025, AAMA (American Architectural Manufacturers Association), Air Barrier Association recognition, and Miami DADE, Salas O’Brien’s Daytona Beach lab specializes in advancing building material standards. It conducts critical testing, including Miami DADE window impact and AAMA evaluations, that guides manufacturers on product improvements and installation methods. This facility not only plays a crucial role in material innovation through R&D and pre-market testing under NDAs but also supports the industry with expert witnesses and insurance analyses to drive forward safety, sustainability, and innovation in construction materials.

How Salas O’Brien can help

Salas O’Brien has teams of building enclosure consultants across North America highly experienced in building envelope design, consulting, testing, and commissioning. We have professionals specializing in different systems and climates and a vast supply of calibrated testing equipment.

We work with numerous business partners such as developers, architects, and construction teams to serve new builds and major renovations and work directly with clients on remediation. Through expert consulting and advanced testing, we can help you unlock energy efficiency, durability, and comfort settings with new benchmarks for high performance. To discuss your project, contact an office near you or one of our contributors below.

For media inquiries on this article, reach out to Stacy Lake, Director of Corporate Communications.

Michael Calabrese

Michael Calabrese has over 30 years’ experience in commercial construction. With a passion for education in building sciences, Mike has led trainings throughout the eastern US in regard to mechanically fastened weather resistive barriers and fluid applied air barrier systems as well as flashing applications. He holds a certification as an ABAA field auditor and has worked on hundreds of projects throughout the Mid-Atlantic region. Mike serves as a Senior Vice President at Salas O’Brien. Contact him [email protected]

Jon Haehnel, CEI, BPI- BA-T BA-P, CABS

With over 20 years of building envelope testing and design expertise, Jon Haehnel focuses primarily on institutional and commercial construction. He has built energy models, reviewed construction documents, specified air tightness targets, trained project teams on how to reach the targets, and tested through to completion to verify targets were met for new construction and renovation projects. His experience includes frequently working with owners, architects, contractors, and engineers to coordinate large or complicated tests. Jon serves as an Associate Vice President at Salas O’Brien. Contact him at [email protected] .

Mickey Leso, PE, LEED Green Associate

Mickey Leso is an expert in building enclosure, roofing, and waterproofing projects. His role includes coordination with internal and external teams, client outreach and support, strategic planning, and business development. He earned an integrated Bachelor/Master of Architectural Engineering degree along with a minor in Architecture from Pennsylvania State University. Mickey is deeply committed to advancing sustainable and green building practices and serves as a Vice President at Salas O’Brien. Contact him at [email protected]

Hesam Shafieyan, P.Eng

Hesam (Sam) Shafieyan brings over 15 years of experience designing, evaluating, and implementing complex building envelope systems to his projects. His expertise spans roofing, waterproofing, windows, curtain walls, facades, and structural elements. Sam has lead a wide array of forensic investigations for significant building envelope and restoration projects across North America, contributing to developing innovative solutions and strategic planning in the building engineering industry. Sam serves as a Senior Vice President at Salas O’Brien. Contact him at [email protected].

Stephen Shanks, CxA, BECxP, NDT Level III

Stephen Shanks is a building scientist and commissioning provider with over 40 years of experience. He possesses a unique blend of expertise in physics and building construction. His knowledge and experience allow him to effectively bridge theory and practice. Stephen is a subject matter expert for Building Enclosure Commissioning (BECx), Air Barriers, Whole Building Airtightness Testing (WBAT), and Thermal-Infrared (IR) Examinations. He is actively engaged in various industry standard and code development committees, including ASHRAE Technical Committees 4.4 Building Envelope Performance and 7.9 Building Commissioning, and ASTM Committee E06 Performance of Buildings. Stephen serves as a Vice President at Salas O’Brien. Contact him at [email protected]

Don Williams

Don Williams is a seasoned expert in building envelope consulting with over 20 years of specialized experience in moisture intrusion prevention and solutions. His expertise and leadership in the field led to founding Moisture Intrusion Solutions (MIS), a team that joined Salas O’Brien in 2023. Don began his career working for a general contractor, laying the foundation for his distinguished professional reputation for addressing and solving complex moisture-related challenges in building envelopes. Don serves as a Principal at Salas O’Brien. Contact him at [email protected].