Projects

Enhancing production capabilities by seamlessly integrating equipment

Confidential, USA

Battery Pack Expansion

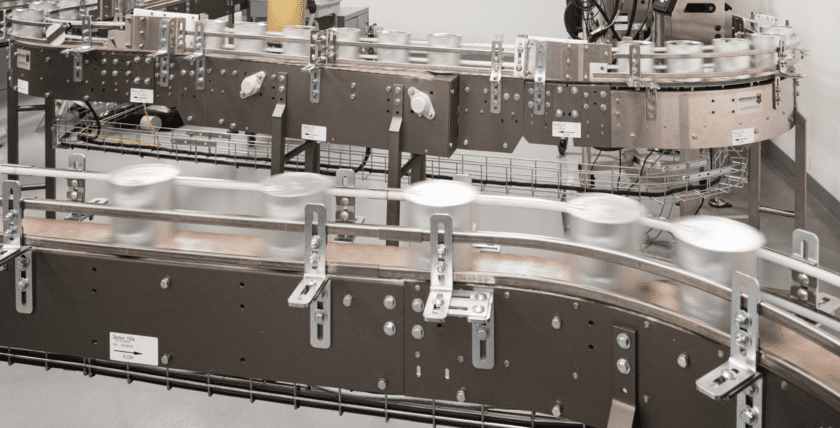

American Battery Systems contacted Salas O’Brien as a part of their production expansion project when faced with the need to modify and expand the types of batteries produced to meet varying client requirements at each stage of production. Their initial manufacturing system had limited adaptability for recipe adjustments and minimal data-gathering capabilities.

Our team reviewed the existing system and then worked with the client to deploy a combination of factory floor programming and higher-level software development to allow varied components to be installed and tested at each operation. In addition to the flexibility added, the system is also designed to check the recipe number of the parts based on an RFID tag on a workpiece carrier at each operation. The system then verifies that the part is at the correct station and is not rejected.

The corresponding recipe is loaded and allows multiple setpoints for each component/test. As the components are installed, each data point is logged into the data collection system, providing true track and trace of their product at each cell as they progress through production to a finished battery pack. In addition, all products have their component part numbers verified in the recipe before installation. All data and recipes are stored in an easily accessible database so that reports we create for our client can be accessed on an on-demand basis.

New products are now added in a fraction of the time by creating recipe points in the new system. Previously, a new model would require programming a hard-coded recipe and completely new installation sequences. The system’s flexibility allows it to run multiple models on the line simultaneously, optimizing production and reducing downtime. Parts can be created and serialized (through track and trace) and then used by the client at other operations with complete tracking throughout the process. Our client now has a best-in-class system with full visibility and a myriad of dashboards and reports for ease of operation, maintenance, and a foundation suited for future expansion.